Training Path for Automotive Repair Apprentices

Automotive repair is a critical trade that ensures vehicles operate safely and efficiently. As cars and trucks become more technologically advanced, the demand for skilled automotive repair professionals continues to rise. Apprenticeships offer a practical pathway for individuals to enter this field by combining hands-on experience with technical training. This article outlines the typical training path for automotive repair apprentices, highlighting key stages, skills development, and certification processes.

Overview of Automotive Repair Apprenticeships

An apprenticeship in automotive repair is a structured program designed to teach the skills and knowledge required to diagnose, maintain, and repair vehicles. Apprenticeships typically last from two to five years, depending on the program and jurisdiction. During this time, apprentices work under the supervision of experienced mechanics while attending formal training sessions.

Initial Requirements and Entry

To start an apprenticeship, candidates usually need a high school diploma or equivalent. Basic skills in math, reading, and problem-solving are essential because automotive repair involves interpreting manuals, diagnosing issues, and performing calculations for parts and systems. Some employers may require a valid driver’s license due to test-driving duties.

Many apprenticeships require applicants to pass an entrance test assessing mechanical aptitude, math skills, and reading comprehension. This ensures candidates have the foundational abilities needed to succeed in training.

On-the-Job Training

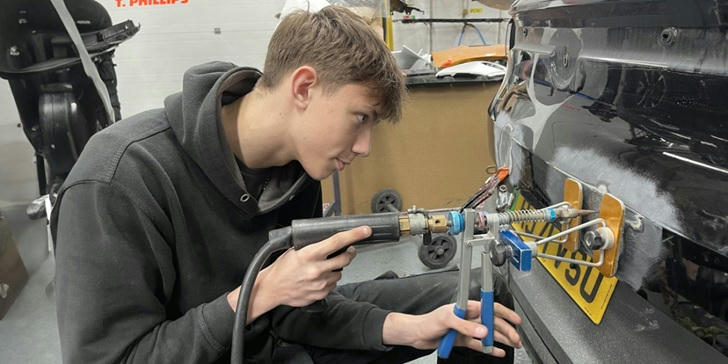

The core component of an apprenticeship is hands-on training. Apprentices learn by working alongside certified technicians in automotive repair shops, dealerships, or service centers. This practical experience covers:

- Inspecting and diagnosing vehicle problems

- Repairing or replacing mechanical parts like brakes, engines, and transmissions

- Performing routine maintenance such as oil changes and tire rotations

- Using diagnostic tools and computer systems to identify electronic issues

- Practicing safety procedures and proper tool use

On-the-job learning allows apprentices to develop technical skills gradually while gaining confidence and efficiency.

Classroom Instruction and Technical Education

Alongside workplace training, apprentices attend classes at vocational schools, community colleges, or training centers. The coursework covers theoretical concepts including:

- Automotive systems and components

- Electrical and electronic diagnostics

- Engine repair and fuel systems

- Emission control technology

- Customer service and communication skills

Classroom education provides a deeper understanding of vehicle mechanics and emerging technologies, complementing the practical experience gained on the job.

Progressive Skill Development

Apprenticeships are typically structured in stages, with apprentices advancing as they demonstrate proficiency. Early stages focus on basic maintenance and simple repairs, while later stages involve complex diagnostics and major system repairs. This progression ensures a comprehensive skill set by the time the apprenticeship concludes.

Certification and Licensing

Completing an apprenticeship often leads to eligibility for certification exams. In many regions, automotive technicians can earn credentials such as the ASE (Automotive Service Excellence) certification. ASE certification requires passing tests in various specialties and demonstrates professional competence.

Certification increases employability and can lead to higher wages and career advancement. Some employers also require ongoing certification renewal to keep technicians updated on industry standards.

Soft Skills and Professionalism

In addition to technical skills, apprentices must develop important soft skills. These include:

- Effective communication with customers and colleagues

- Time management and punctuality

- Problem-solving and critical thinking

- Adaptability to new technologies and repair methods

- Professional ethics and responsibility

Building these qualities helps apprentices transition into respected professionals in the automotive repair industry.

Work Environment and Conditions

Automotive repair apprentices work in garages, dealerships, or service shops. The environment can be physically demanding, involving standing for long periods, lifting heavy parts, and working in varying temperatures. Apprentices must also follow strict safety protocols to prevent injuries.

Work hours may vary depending on the employer and workload, with some shops operating evenings or weekends. Flexibility and stamina are important for success.

Career Outlook and Advancement

The automotive repair industry is expected to grow steadily due to increased vehicle complexity and the need for maintenance and repair services. Apprentices who complete their training and obtain certification have strong job prospects.

With experience, technicians can specialize in areas like diagnostics, transmission repair, or hybrid and electric vehicles. Advancement opportunities include becoming master technicians, service managers, or opening independent repair businesses.

Summary

The training path for automotive repair apprentices combines on-the-job experience with classroom learning to develop a comprehensive skill set. Through progressive training stages, certification, and professional development, apprentices prepare for rewarding careers in a vital industry. Commitment to continuous learning and adaptability to technological changes remain key for long-term success in automotive repair.